Processes

Processing adds value

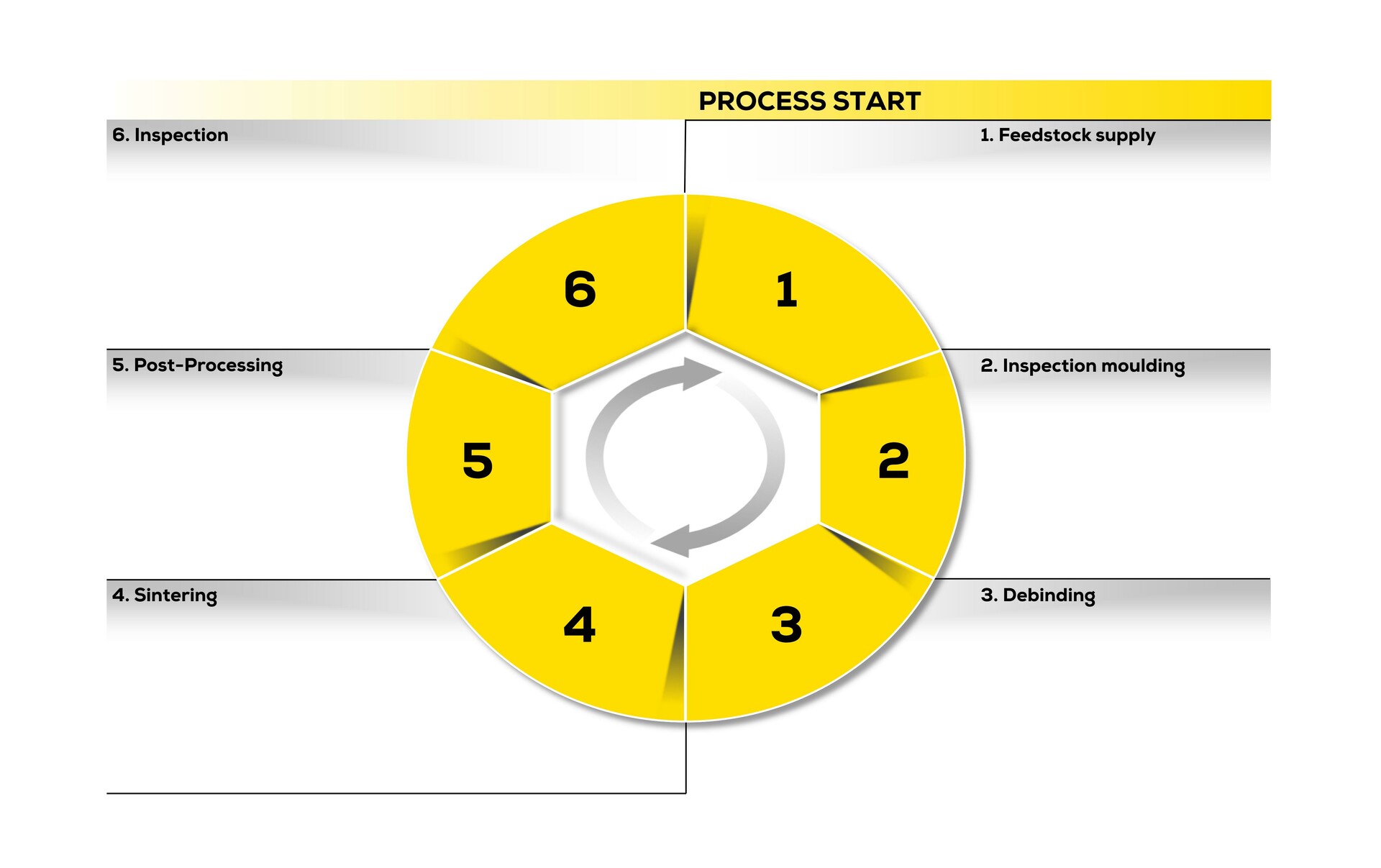

The MIM method combines two already known manufacturing processes. One is the plastic injection moulding and the other one the sintering of metal powder compacts. Metal injection moulding brings both together.

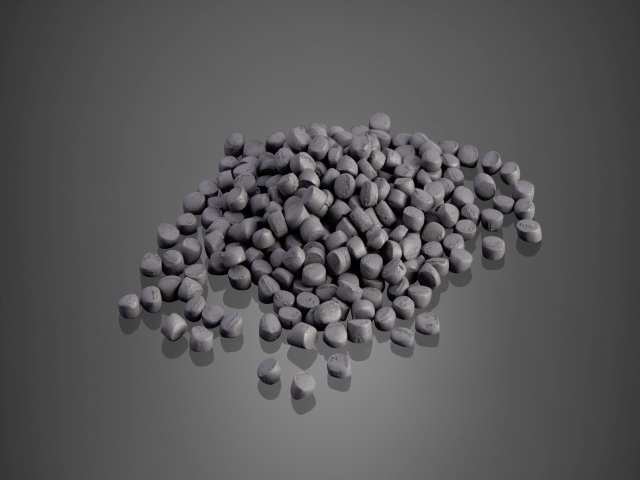

The feedstock, a mixture of fine metal powder and plastic granules, represents the raw material. This can be processed by conventional injection moulding machines to form parts. Then the plastics, which is required for shaping will remove via the debinding process.

The sintering process finally gives the components their final mechanical properties. A further processing is usually not necessary. However, various post-processing processes can be applied for finishing the parts.

Our processes

Customized products

The wide vertical range of manufacture of our finished products is based on each product completing several peripheral product stages or processes. This procedure permits customized mass production which meets the specific product requirements and the needs of the customer.

The continuous improvement of the manufacturing processes and methods applied reflects Reich MIM’s investment in state-of-the-art facilities and in the professional development of a new generation as well as existing personnel.

- selection and use of binder systems and metal alloys according to purpose or customer request

-

injection moulding machines with handling systems

-

production cells as combination of injection moulding machine, robot systems and peripherals

-

production facilities for catalytic debinding process

-

debinding production facilities for water-soluble binder systems

-

batch sinter furnaces

-

continuous furnaces

-

mechanical post-processing in case of tight tolerances and fits

-

heat and surface treatment in cooperation with our partners

-

component assemblies

-

overmoulding of MIM components with plastic (insert/outsert technology)

-

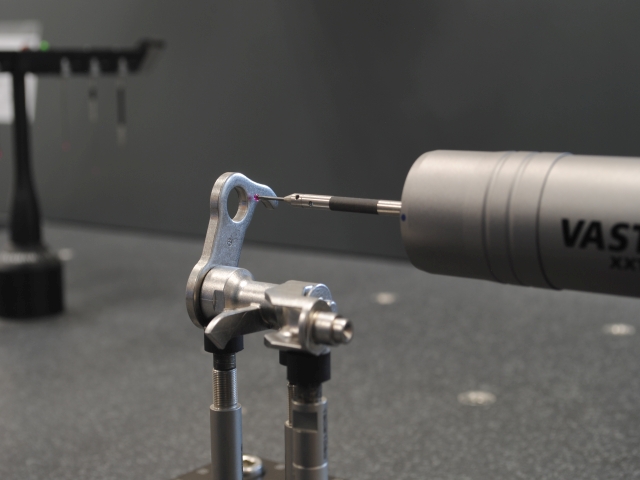

3D/2D coordinate measuring technology

-

contour and roughness measurement

-

analytical method of spectral analysis

-

metallography

-

hardness testing technology